Drawn aluminum plate is an aluminum plate material obtained by drawing the surface of aluminum plate. Wire drawing treatment refers to repeatedly rubbing the surface of aluminum plate with tools such as sandpaper, which makes the surface of aluminum plate form fine filiform textures. This process can adopt mechanical wire drawing and chemical etching wire drawing. Mechanical wire drawing is the most common, and the surface of aluminum plate is rubbed in one direction or in many directions by tools such as abrasive belt on the wire drawing machine, thus producing filiform effect.

For example, in the field of architectural decoration, the aluminum sheet is usually fixed on a workbench, and then drawn with a specific mesh of abrasive belt at an appropriate speed and pressure by automatic drawing equipment. The thickness of wire drawing varies with the mesh number. For example, the wire drawn by 80 mesh abrasive belt is thicker, while the wire drawn by 180 mesh abrasive belt is relatively thinner.

characteristic

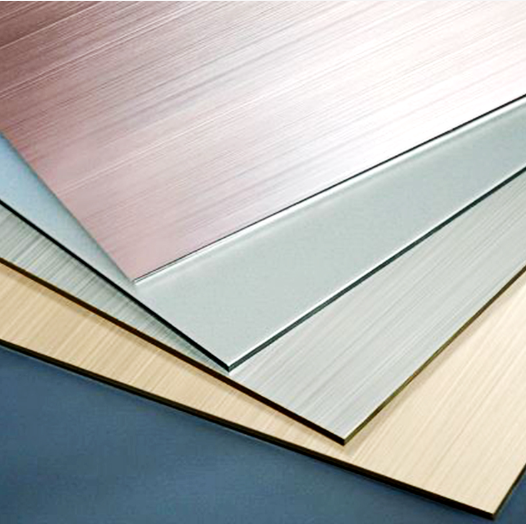

Aesthetics: Drawn aluminum plate has a unique metallic texture and silk effect, which can improve the appearance grade of products. Its texture can be customized according to different design requirements, such as straight lines and random lines. Straight wire drawing can create a simple and smooth visual feeling, which is often used in electronic product shells, furniture decorative strips, etc. Random drawing is more artistic and has a good application in some creative decorative products.

Abrasion resistance: Because its surface has been drawn, a relatively abrasion-resistant texture layer has been formed. Compared with ordinary aluminum plate, it is not easy to be scratched in daily use, and can maintain the surface integrity to a certain extent. For example, the brushed aluminum plate used in the elevator car can maintain its appearance for a long time even in the case of frequent personnel entry and exit and collision of objects.

Anti-skid performance: the drawing texture increases the friction on the surface of aluminum plate, making it have good anti-skid performance. This feature enables it to be applied in some occasions that need anti-skid, such as stair treads and operating platforms of industrial equipment. In some humid environments, such as the aluminum floor of swimming pool, the slip resistance of brushed aluminum can effectively prevent people from slipping.

application area

Architectural decoration industry: used for building facade, curtain wall, indoor wall decoration, ceiling, etc. In the facade of the building, brushed aluminum plate can be matched with glass, stone and other materials to create a modern and fashionable architectural style. For example, the curtain wall of some high-end commercial buildings is made of brushed aluminum plates. Under the sunlight, the grain on the surface of the aluminum plates will produce a unique light and shadow effect, which will enhance the visual appeal of the building.

Electronic product industry: it is commonly used in the shell of electronic products, such as the shell of notebook computer and the back cover of mobile phone. The metallic texture of brushed aluminum sheet can improve the quality of electronic products, and its heat dissipation performance is also helpful to the stability of electronic products. For example, the shell of some high-performance notebook computers adopts brushed aluminum plate, which can effectively dissipate the internal heat while ensuring the beauty.

Transportation industry: It has applications in automobile interior and train compartment interior. In automobile interior, brushed aluminum plate can be used for dashboard decoration, door interior trim panel and other parts to increase the sense of exquisiteness and technology of interior.